Drawing Review & Planning

Customer drawings and technical specifications are carefully reviewed, followed by production planning to define an efficient and accurate manufacturing sequence.

A well-planned manufacturing facility layout enabling efficient fabrication,

assembly, testing, and smooth material flow across all processes.

Production activities are overseen by our experienced engineering team to

maintain process control, quality discipline, and consistent product

reliability.

Dimensional and visual inspections are carried out at defined production

stages

to ensure accuracy, consistency, and strict adherence to approved

drawings.

Each radiator is individually tested to verify leak-free performance under

controlled pressure conditions.

TransVolt Engineering Pvt. Ltd. operates a dedicated manufacturing facility for pressed steel transformer radiators and fabricated assemblies. The plant is equipped with modern fabrication machinery and a structured production layout to ensure dimensional accuracy.

Defined inspection stages and disciplined processes enable consistent quality, safe operations and dependable supply for power and distribution transformer applications.

Delivering reliability through disciplined manufacturing.

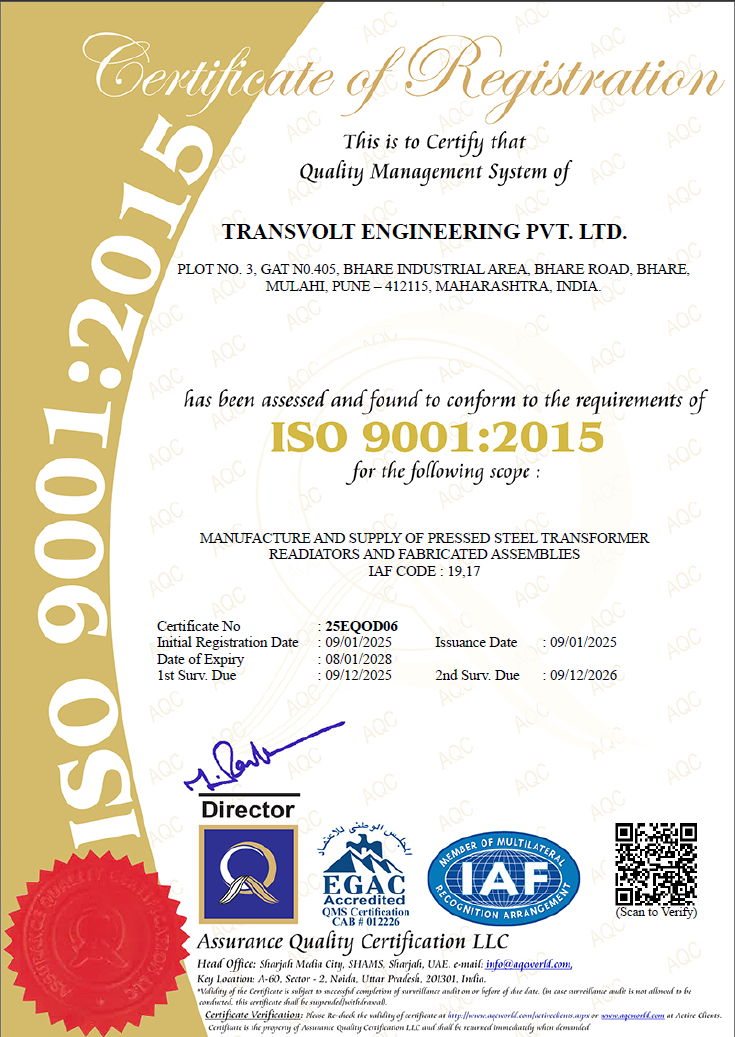

Our ISO 9001:2015 certified quality management system demonstrates commitment to controlled manufacturing processes and consistent product quality across all operations.

Systematic inspections, documentation and monitoring ensure compliance with international standards and long-term product reliability.

Certified processes that ensure confidence and consistency.

Our manufacturing operations are supported by experienced engineers and skilled technicians working with precision tooling and controlled fabrication processes. Engineering oversight ensures adherence to specifications, process stability, and consistent execution across production stages.

Continuous process optimisation enables reliable radiator performance while meeting customer-specific technical requirements.

Precision driven by technology, powered by expertise.

Customer drawings and technical specifications are carefully reviewed, followed by production planning to define an efficient and accurate manufacturing sequence.

Radiator elements are precision-pressed, welded, and assembled for structural strength and seam integrity.

Dimensional inspection is carried out to match drawing tolerances, followed by pressure testing to confirm leak-proof performance before surface finishing.

Surface preparation, primer, and finish coating are applied as per customer specifications, followed by secure packing and systematic dispatch for safe delivery.

Looking for a reliable transformer radiator manufacturer? Let's discuss your requirements.

Get in Touch